Fines stack up for Cowlitz County sawmill after worker loses fingertip to machine

TUMWATER — A sawmill with a history of safety violations is facing $153,000 in fines after a workplace injury lead to a worker’s fingertip having to be amputated.

The Washington Department of Labor & Industries (L&I) recently cited RSG Forest Products Inc. for numerous safety violations after opening an inspection in connection with the injury.

When L&I inspectors went to the company’s Kalama mill they found a dozen unsafe practices -- some connected to the machine the worker was using when the injury occurred. Others were unrelated to the incident that were still risky to workers at the facility.

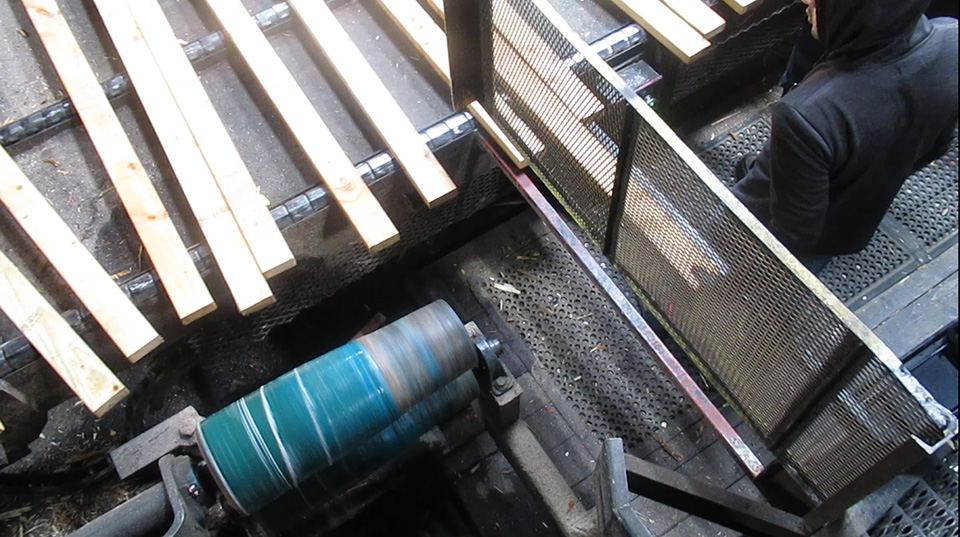

The injury happened last fall to a man working at the RSG mill. His job was to arrange and place long pieces of lumber onto a conveyor system. When the worker held on to one of the boards too long, a powerful roller shot the board and his hand into a steel plate. The tip of his finger had to be amputated as a result of the injury.

Inspectors captured video of the machine in operation (an audio descriptive version is available) and found that workers could reach past the guard bar on the machine. Since the incident, the company has installed a mesh panel above the existing guard bar to discourage the unsafe practice.

History of ignoring safety rules

RSG Forest Products has been inspected by L&I nearly a dozen times in the last eight years. Most were follow up inspections after worker injuries. Inspectors repeatedly found the same violations, including lack of machine guarding, and not following energy control procedures.

Energy control incidents happen when machinery unexpectedly or accidentally gets power and starts up because the power source isn’t shut off or “locked out.” Of the dozen violations found in this inspection, five stem from not following energy control and lockout procedures on dangerous equipment including the rolling machine shown in the video.

The other violations include not adequately guarding chains, sprockets, and other moving parts on machines and conveyor systems. L&I also cited the company for not having railings around raised walkways or platforms above or near dangerous equipment, and for workers using compressed air to clean sawdust from their clothing.

While they were at mill with RSG’s safety manager, L&I inspectors saw workers entering hazardous areas without locking out the equipment. Workers also told inspectors they are regularly allowed to climb onto moving equipment while it was running.

“If management did nothing to stop workers from entering hazardous areas while L&I inspectors are standing on site, it’s a sign these dangerous work practices are the norm, not the exception,” said Craig Blackwood, assistant director for L&I’s Division of Occupational Safety and Health.

“These serious and preventable injuries that keep bringing us back to RSG’s sawmills won’t stop until management makes safety a priority,” said Blackwood. “We hope this citation and fine will prompt them to do the right things to protect their workers."

The full citation, including a breakdown of the fines, is available online. RSG Forest Products is appealing L&I’s decision.

Matt Ross, L&I Public Affairs, 360-706-4857.

Communication Services | www.Lni.wa.gov/news-events

See the latest L&I news releases